Machining, Sawing and Surface Coating Services

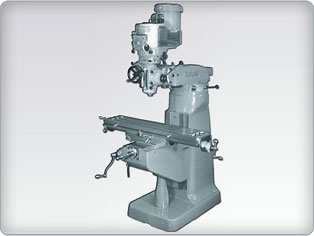

(click on thumbnail to enlarge)

(click on thumbnail to enlarge)

Machining is a group of processes in which a shape is generated by removing unwanted material. Machining can be used to make a component from stock material but more often it is used as a secondary process to impart a shape or a level of precision to a manufactured component that cannot be achieved otherwise. Shape restrictions exist for some machining processes.

Sawing is the process of cutting raw materials to achieve the required length, generally for use at subsequent workstations.

Surface Coating is the process of adding a coating to a metal product for the purpose of corrosion resistance and/or cosmetic value. Powder coat paint, wet paint, anodizing, plating, phosphate, and silk-screening are available.

Loyal Manufacturing Corporation's Machining and Saw Services have provided its customers with precision metal products since 1975. Utilizing various brands of mill, lathe, screw machine, drills, surface grinders & saws, Loyal Manufacturing can provide light to medium volume, repeatable products. Services offered include turning, tapping, countersinking, knurling, drilling, milling, surface grinding, deburring, belt sanding, and cutting, We have a wide range of standard tooling in inventory. Our dedicated and experienced employees strive for "Total Customer Satisfaction" and "On Time Shipping" in every part produced. Over the years many types of material have been processed such as carbon (mild) steel, coated carbon steel, aluminum, copper, brass, stainless steel, & plastic (including printed circuit boards). Refer to the "Materials Processed" section of this page for specific materials/grades.

Surface finishing - Loyal Manufacturing utilizes several outside service partners for painting (wet & powder coating), plating, anodizing, phosphate, & silk-screening.

Other service vendor partners - Loyal Manufacturing can support parts that require heat-treating, laser or water jet cutting, tight tolerance machining, etc. through our nearby network of quality service vendor partners. Due to our diverse vendors base, pricing is often times more competitive than shops that have these services in-house.

Loyal arranges all transportation for these outside services and take ownership for the processes, subjecting all products to our inspection standards as if they were produced at Loyal.

Following completion of all customer parts, each process is analyzed to insure maximum efficiency in our manufacturing methods. Whether we are supporting the development of a unique prototype, small runs or large runs, we have the experience to suit most any need. Our goal is to find the most efficient solutions possible to maximize the value of the products supplied to our customers.

Refer to the machine specifications listed below, to see our capabilities and how we can support your fabrication needs.

Use the "Request Information" selection button to contact us, and attach your design documentation for our Engineering Department to review, then work with our Engineering Department to confirm your design and receive your requested quote.

Machining, Sawing and Surface Coating Capabilities

- Machines in Our Shop

- General Machining

Loyal has a type J Bridgeport model F-362-00-242 mill (see above section under DOWNLOADS for PDF file), South Bend model CL117D lathe with (16" swing w/ 48" bed), Brown & Sharp model 2 screw machine (up to 1.25" round x 24" length. and including: Special collets for 1 1/8" hex, 1" hex, and 5/16" square. Coarse and fine threading ability from 1/4" - 1/2" + various pipe threads). Powermatic model 200 drill press, Powermatic model 1150 drill press, Buffalo model 14 multi spindle drill press, and a Spunger model NDP15 drill press. For sawing, Loyal has a Wells model 8M horizontal band saw, Continental model FC vertical band saw, Fong Ho model FHC 275SA lubricated chop saw, and a DeWalt model D28715 non lubricated chop saw.

Surface preparation

Loyal Manufacturing has two Falls Metal model 111 deburr machines for flat parts and numerous die grinders, orbital sanders and specialty sanders for non flat parts. Loyal also has a Progress Machine PMC-158.5 stroke sander for larger, repetitive parts, G&P model G-72 belt sander, G&P model B-2572-2 belt sander, and a high speed Chas F L ‘Hommedieu polishing lathe. Additionally, Loyal has a Rockwell/Delta model 24-150 surface grinder with a 6" x 12" bed and a South Bend FSG2A20 hydraulic surface grinder with 18" x 6" bed with 9" height clearance and auto feed for X and Y axis.

- Materials Processed

- Carbon (mild) steels: (cold rolled, hot rolled, hot rolled pickled and oiled, draw quality)A36, C1018, 12L14, & schedule 40 in tube, pipe, bar, angle, coil, & sheet. Galvanized and galvannealed coated carbon steel in sheet & coil. Aluminum 3003H14, 5052H32, 6061T6, 6063T5, in sheet, tread plate, bar, tube, coil, extrusion, & angle.

Aluminized sheet.

Stainless steel 301, 304, 310, & 316 w/ #4 & 2B finishes in sheet, bar, tube, & coil Brass alloy 260 and 110 copper in sheet, bar & tube Plastic, lexan, & delrin in sheet (But not limited to, contact us for other inquiries).

- Surface Finishing

- Loyal Manufacturing utilizes several outside service partners for painting (wet & powder), plating, anodizing, phosphate, & silk-screening. Loyal arranges all transportation for these services and takes ownership for the processes as if they were our own.

- Other Service Vendor Partners

- Loyal Manufacturing can support parts that require heat-treating, laser or water jet cutting, tight tolerance machining, etc. through our nearby network of quality service vendor partners.

- Industries Served

-

- Climate Control Enclosures

- Commercial Furniture Brackets & Shelves

- Commercial TV custom vesa brackets LCD / LED / Plasma

- Custom Carrying Cases

- Custom OEM Circuit Board Enclosures

- Education Audio/Video Equipment

- Electric Motor Bases

- Electrical Enclosures & Panels

- Food Service Industry Brackets, Enclosures, etc

- Furnace & Air Conditioning Brackets, Panels, etc

- Health & Beauty - tanning bed components & brackets

- Industrial Lighting brackets HID / LED

- Industrial Plumbing Valve Enclosures

- Medical Devices

- Military Brackets & Enclosures

- Pet Supply Brackets & Enclosures

- POP Cash Storage Cabinets

- Printed Circuit Boards

- Public Utility Safety Testing Devices

- Safe & Vault Brackets

- Security Equipment & Devices

- Specialty Fasteners/Brackets

- Transportation Safety

Print This Page

Print This Page